In order to implement lean management work well, improve the work enthusiasm of all employees, and create a lean improvement atmosphere of cost reduction and efficiency increase, Guangdong Laya New Chemical Technology Co., Ltd. carried out lean production activities from April 18th to April 21st. Since its launch, the activities have received strong support from company leaders and positive responses from employees.

April 18th

Lean Production Training

On April 18th, General Manager Xinlin of Laya, department heads, and some Laya employees participated in workplace work norms training. After the meeting, all attendees rated the 24 training items, providing a reference direction for corporate culture construction.

Subsequently, Laya conducted learning on topics such as "Lean Operations Management System", "Standardization of Work Instructions", "Principles of Process Standardization and Inspection Points for Process Standardization Development". After the meeting, attendees divided into four groups to conduct standardization inspections on the four processes of water bath, boxing, palletizing, and sealing in the production line.

April 19th

Standardized Work and Learning for Managers

On the morning of April 19th, Laya conducted a standardized learning session for managers, with General Manager Xin Lin, department heads, and some Laya employees participating in the meeting. The conference theme revolves around "clarifying the definition of management", "daily work content of management personnel", and "standardization and modularization of management work", aiming to improve the efficiency and level of company management, and make Laya's management system more systematic and standardized.

In the afternoon, Laya held an analysis meeting on "OEE data", analyzed and investigated the OEE data of the company's three production lines, and proposed relevant countermeasures for the existing problems.

April 20-21

Manual labeling monitoring

On site OEE improvement

OEE improvement

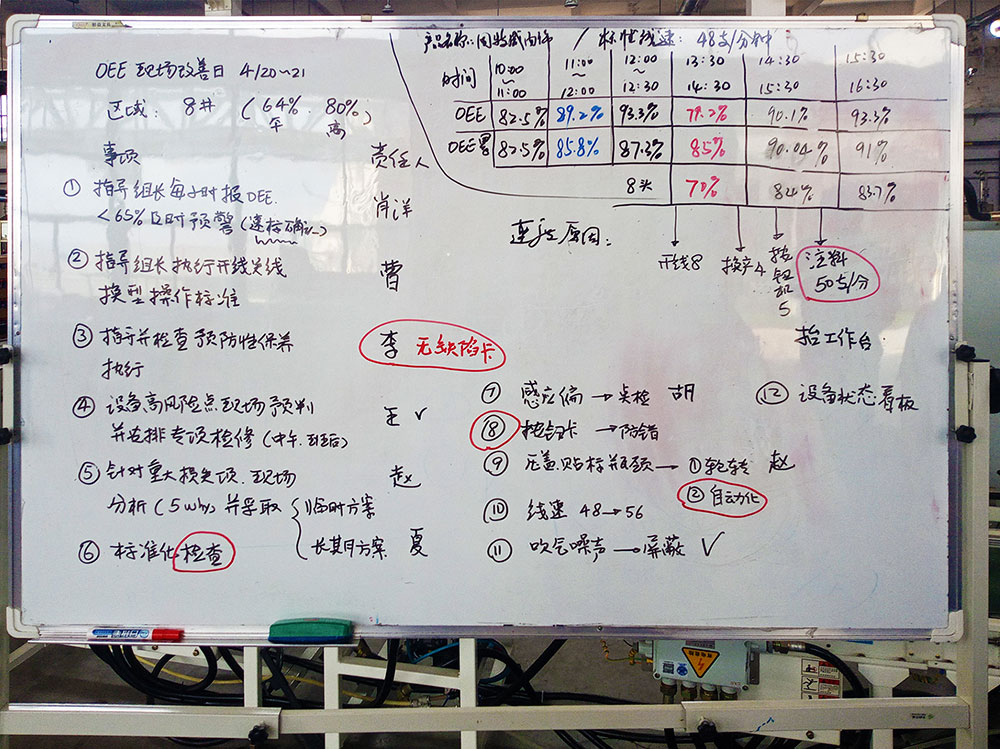

To enhance the awareness of OEE among employees, from April 20th to 21st, Laya carried out on-site improvement activities for two consecutive days. The activity team selected one of the production lines for OEE analysis, used OEE theory and tools to identify the shortcomings of the production lines and make improvements. During this period, the team continued to monitor and improve the key parameters of OEE, and through unremitting efforts, the production line and other equipment were further improved.

Subsequently, the production department and equipment engineering department of Laya clarified the implementation time, project content, responsible persons, and other information of the "OEE Kanban Implementation Status". They established skill evaluation standards for personnel at the master and independent operator levels, and developed a captain skill matrix for data situations that affect OEE. They also convened equipment engineering personnel to record daily work content on the Kanban. Finally, a detailed plan was made for the next lean coaching task.

Lean production is not an overnight task and requires regular implementation. In the future, Laya will strictly implement lean production management to every employee and every work process, continuously promote lean management projects, achieve cost reduction and efficiency increase, build a benchmark enterprise for lean production, and contribute to Laya's high-quality development.